Projects

Lab Focus

Emerging manufacturing processes are at the heart of the Dalton Lab, to produce advanced biomedical materials that can be translated to an application. We specialize in melt electrowriting, but also hybridize other advanced processes to create new objects with distinct properties that outperform existing gold standards. In particular, we work with 3D printing technologies towards full digitization of biomaterials, allowing rapid research cycles and innovative biomedical products.

Accessibility

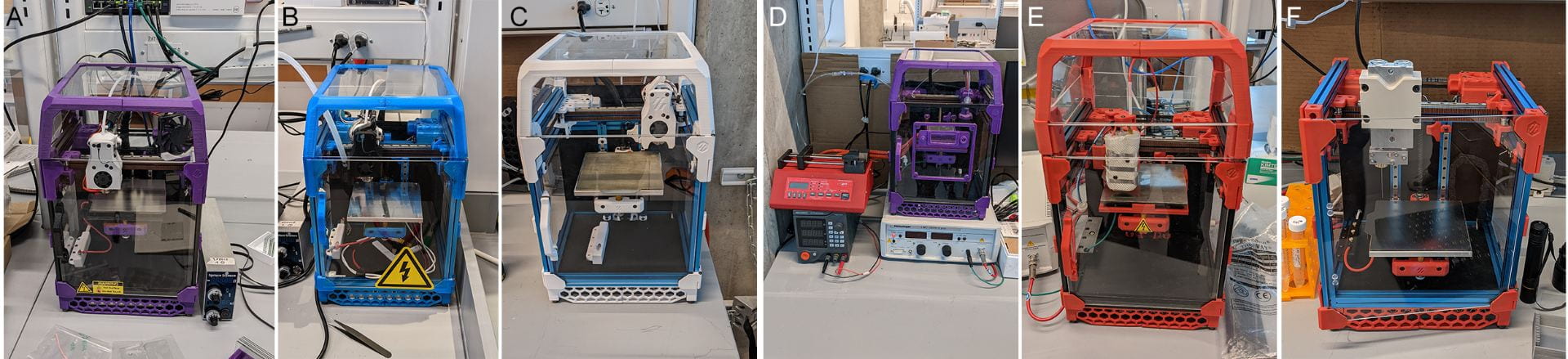

We initiated an open-source 3D printer hardware ecosystem to improve accessibility of melt electrowriting. We built the “MEWron” on the back of the phenomenal Voron platform to improve functionality, usability, and capabilities of this technology increases adoption and helps move high resolution additive fabrication techniques further.

Pushing the Limits of Fabrication

Expect anything to happen in this space! The principle of the lab is to not do incremental research but follow the threads of research which are capable of transformative change. We want to be disruptive, we want to invent new fields of research and we achieve this through curiosity and taking note of the times we look at data and say “That’s weird!”.

This is why it is difficult to determine where our next breakthrough comes from, and which projects in the lab turbo-charge step-changes in manufacturing capabilities. It could be in microfibers, nanofibers, skin research, hydrogels or structural designs. We LOVE taking tools from other fields and applying them in ours to not reinvent the wheel and perform impactful research that is also economical.

Pushing the envelope of fabrication includes modulating mechanics, materials, printing conditions to selectively tailor scaffold properties and provide unique solutions to a variety of engineering challenges. We want to transform expectations of what’s possible.

Applications

We fabricate new materials, so that they can be applied to a spectrum of applications. We focus on biomedical materials but also push the boundaries for mechanical, morphological, and chemical properties of high-performance environments. Hybrid fabrication, the use of multiple fabrication technologies to minimize deficiencies of each individual technology, is utilized to achieve specific mechanics and morphologies designed to match tissue properties.